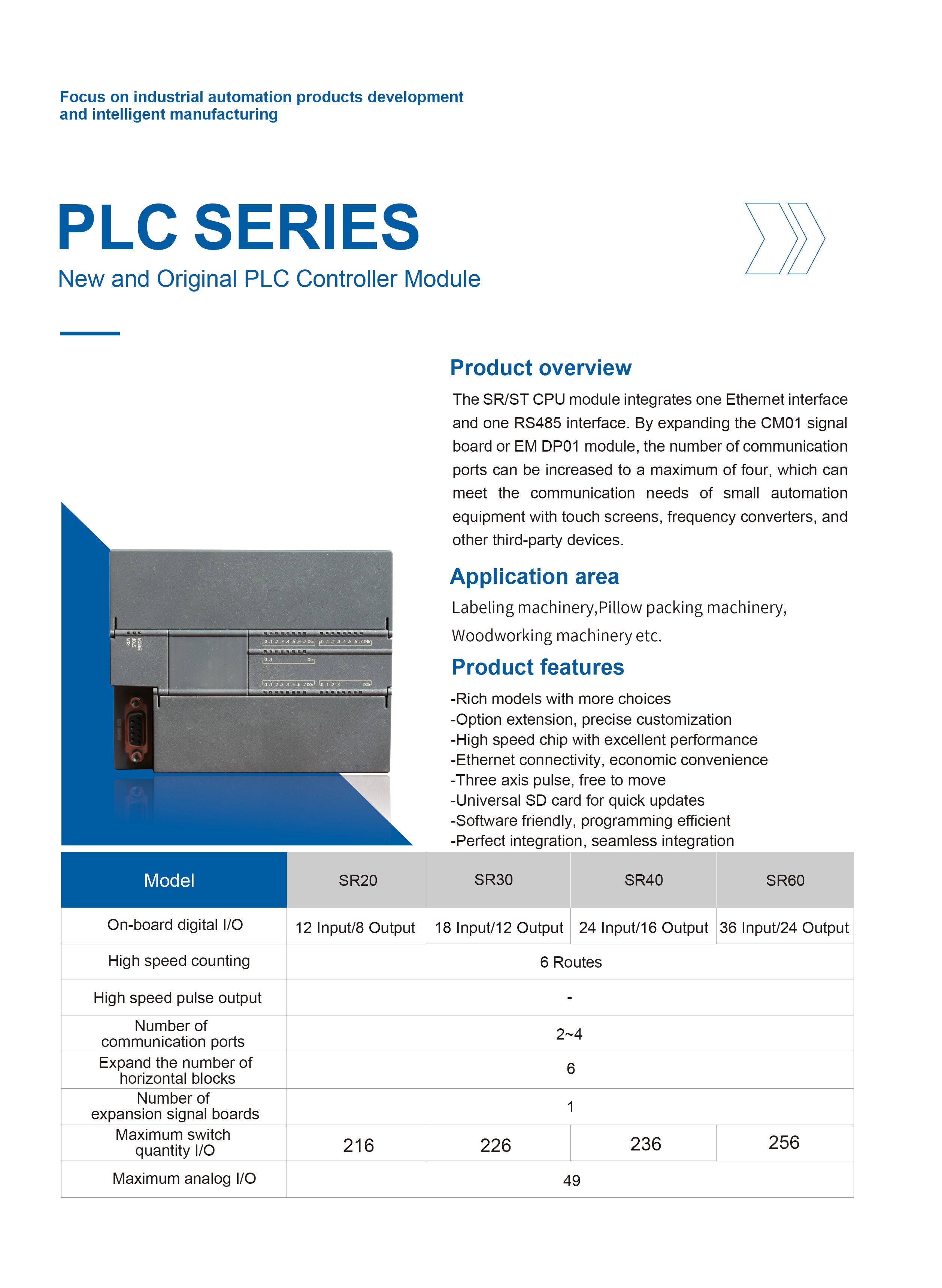

The PLC SR40 is a cutting-edge automation control module designed for industrial applications. With 24 inputs and 16 outputs, it provides the flexibility and power necessary to manage complex manufacturing processes effectively.

Key Advantages:

Application:

In the realm of industrial automation, the PLC SR40 Standard PLC Module is a powerful tool that enhances the efficiency and reliability of manufacturing processes. With 24 inputs and 16 outputs, this PLC module is designed to cater to the demanding needs of various manufacturing applications.

Optimizing Production Lines

Imagine a manufacturing facility producing automotive components. The PLC SR40 can be seamlessly integrated into the production line to control various machinery, including conveyor belts, robotic arms, and quality control systems. By receiving real-time data from sensors (such as proximity and temperature sensors), the PLC can make instantaneous decisions to optimize workflow.

For instance, when a sensor detects a fault in the machinery, the PLC can quickly halt production, alerting operators to the issue. This feature prevents costly downtime and ensures that quality standards are maintained throughout the production process. Additionally, the PLC can coordinate multiple machines to work in harmony, ensuring that the production line operates at peak efficiency.