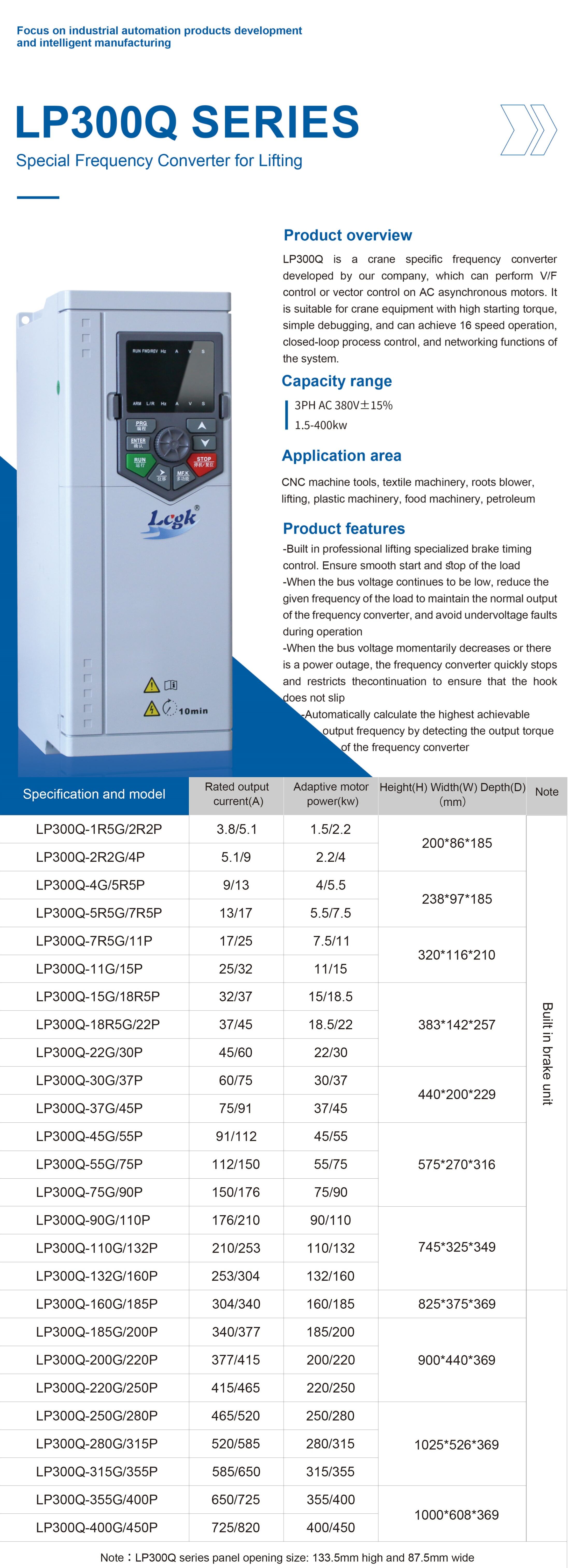

The LP300Q is our company’s cutting-edge frequency converter, crafted for crane-specific applications. It provides both V/F control and vector control for AC asynchronous motors, making it perfect for cranes that need high starting torque. Designed for ease of use, it features simple debugging, supports 16-speed functionality, closed-loop process control, and system networking features.

The LP300Q Frequency Converter for Lifting is designed for manufacturing facilities, where efficient lifting systems are crucial. This converter enhances the performance of cranes and lifts, providing smooth and precise control for improved production efficiency and safety.

Advantages:

Application:

Manufacturing facilities often rely on lifting systems for various processes, such as assembly lines, material handling, and packaging. The LP300Q Frequency Converter for Lifting enhances the performance of cranes, lifts, and conveyors in these environments, making it a critical component for optimizing manufacturing operations.

For example, in an assembly line where components need to be lifted and positioned accurately, the LP300Q allows for smooth and precise control over lifting speeds. This ensures that materials are handled carefully, reducing the risk of damage and improving overall production efficiency. The ability to adjust lifting speeds based on load requirements further enhances the flexibility of manufacturing processes.

Moreover, the LP300Q’s energy-efficient operation contributes to significant cost savings over time. Its advanced features, such as intelligent fault detection and protection against overloads, ensure that lifting operations remain safe and reliable. By integrating the LP300Q into their systems, manufacturers can improve productivity, enhance safety, and reduce operational costs, making it an invaluable asset for any manufacturing facility.