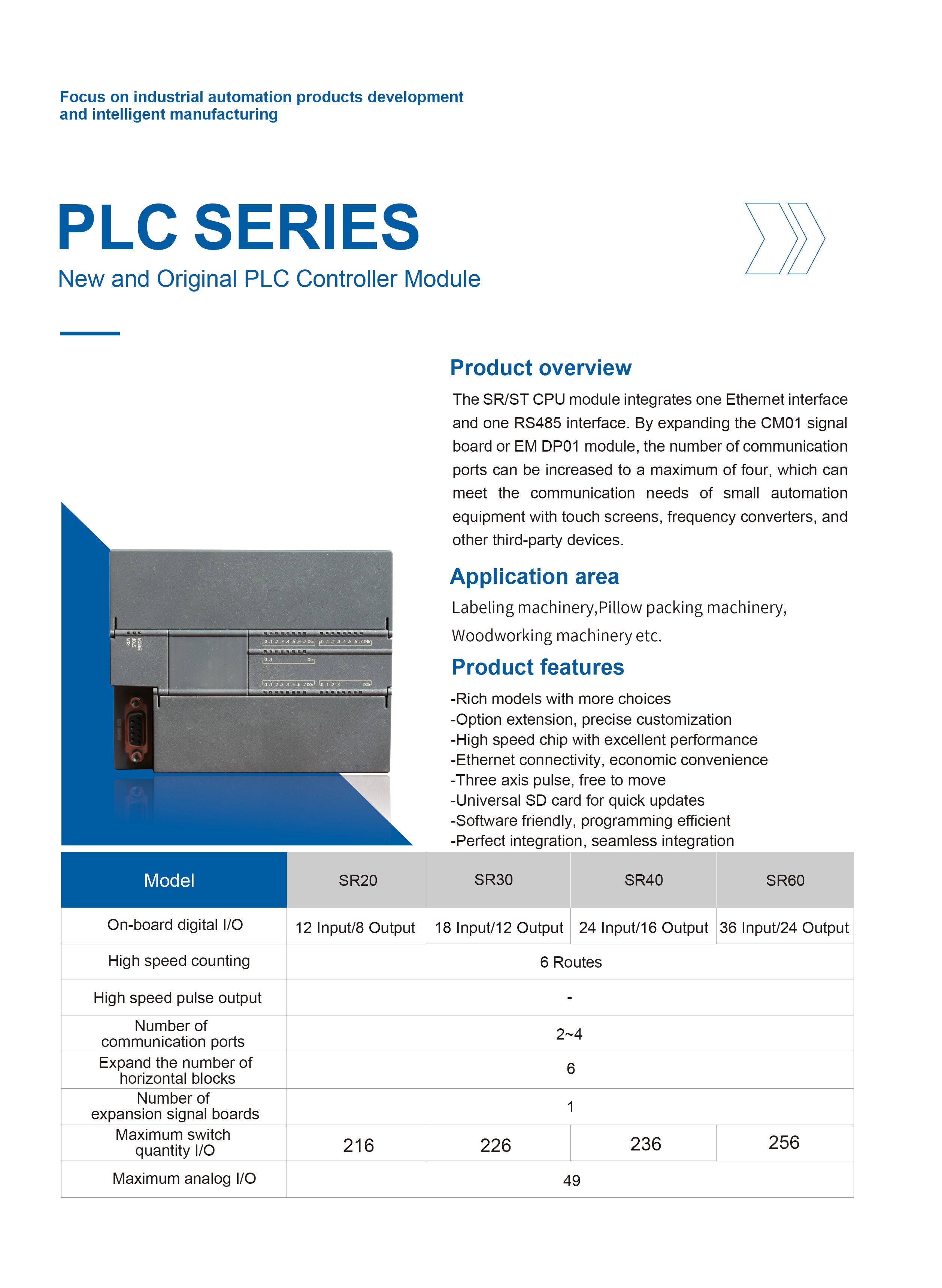

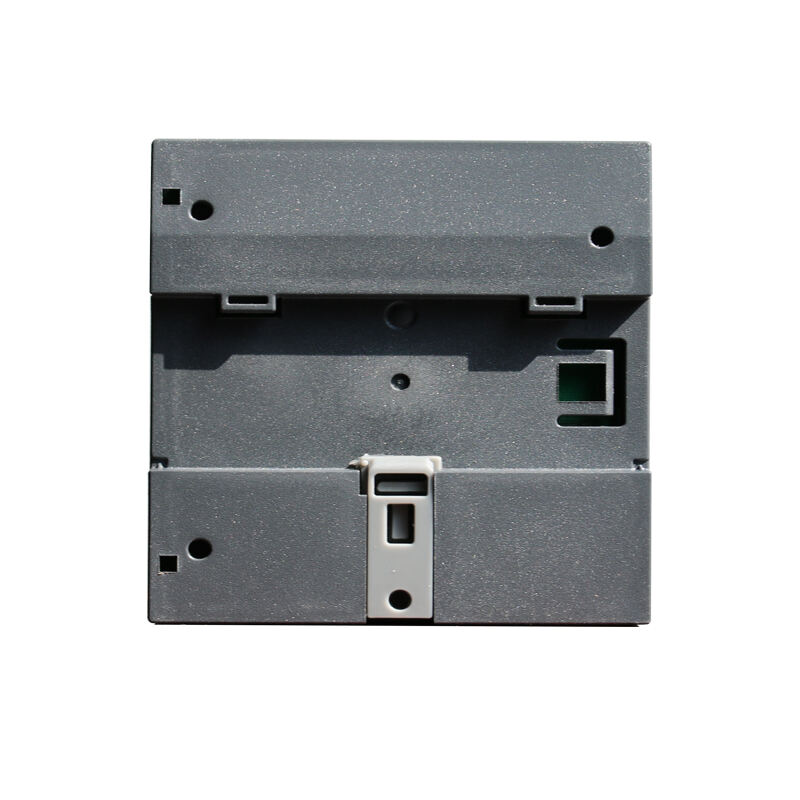

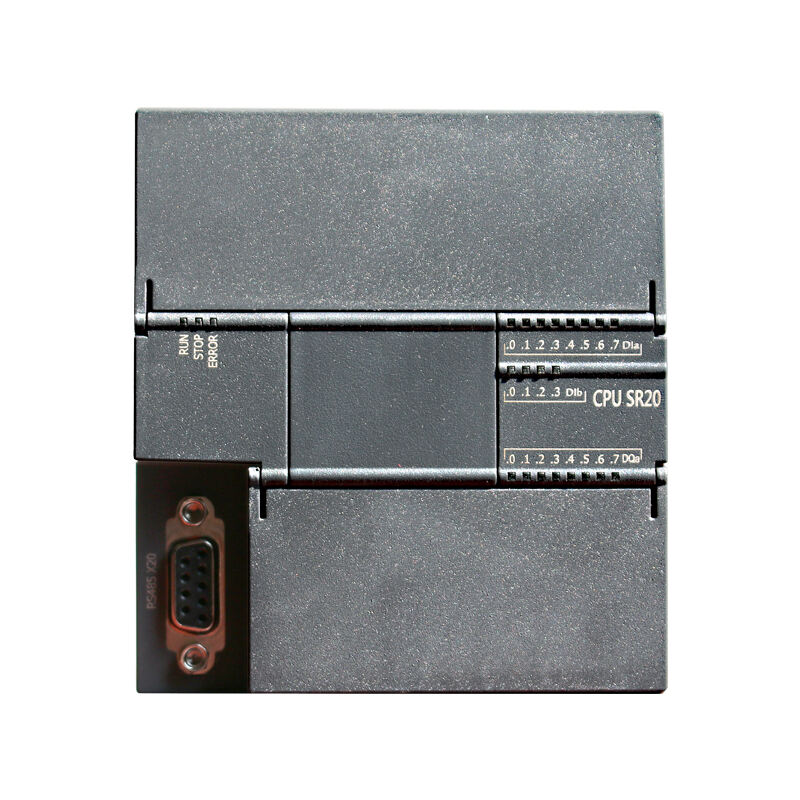

The PLC SR20 is a cutting-edge industrial automation controller designed for seamless integration into manufacturing processes. With 12 inputs and 8 outputs, it offers the flexibility and control necessary for managing various machines and systems efficiently.

Advantages:

Advantages:

Consider an automotive assembly line where the PLC SR20 is employed to manage robotic arms, conveyor belts, and quality control systems. With its 12 input and 8 output configuration, the PLC can effectively monitor sensors that detect the presence of components on the assembly line. It can also control actuators that manage the movement of parts, ensuring that each piece is assembled in the correct order.

For instance, the PLC can be programmed to detect when a car body reaches a specific point on the conveyor. Once detected, the PLC can activate the robotic arm to perform welding or painting, significantly reducing the risk of human error and increasing the speed of production. The relay outputs allow direct control of heavy machinery, which is essential for tasks that require high voltage, ensuring safe and reliable operation.

Moreover, the flexibility of the PLC SR20 allows it to be integrated into existing systems without major overhauls. It supports both 220 V AC and 110 DC power supply options, making it adaptable to various setups. This adaptability means that factories can upgrade their automation systems without incurring excessive costs, facilitating a smoother transition to advanced technology.