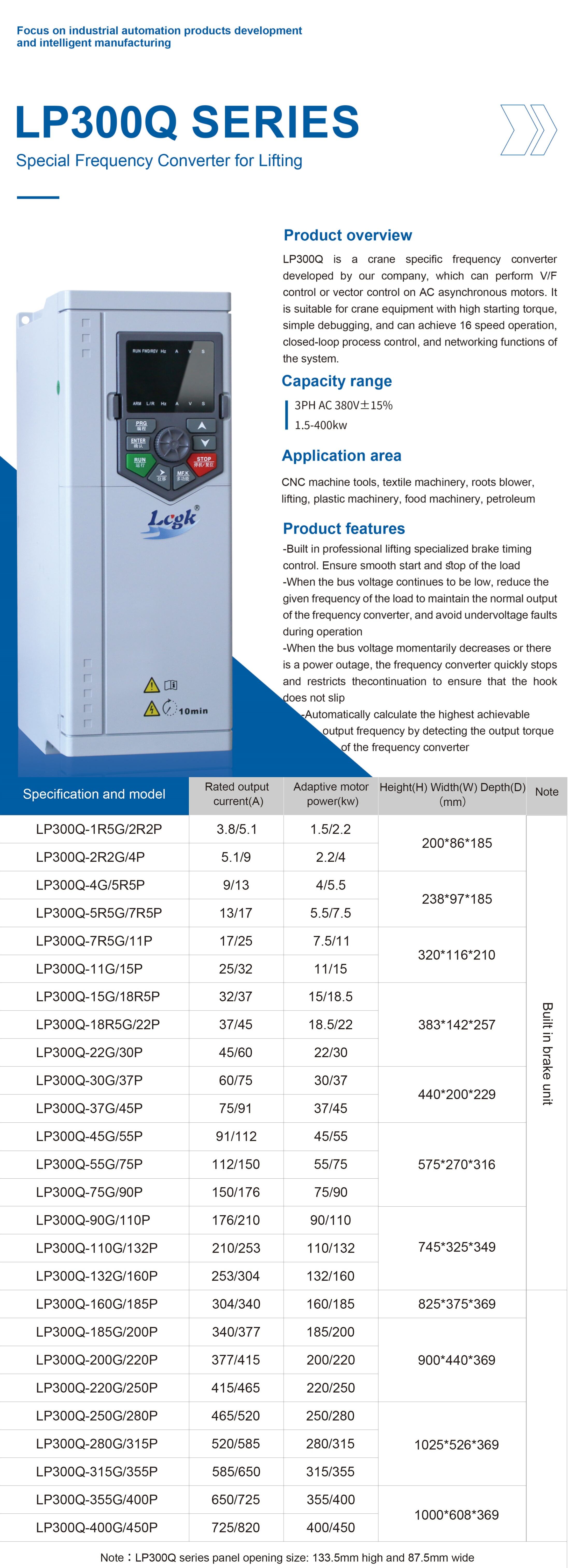

Introducing the LP300Q, a frequency converter specifically engineered for crane operations by our company. This versatile device enables V/F control and vector control of AC asynchronous motors, tailored for equipment demanding high starting torque. Its straightforward debugging process allows for easy setup, while supporting 16-speed settings, closed-loop process control, and integrated networking capabilities.

The LP300Q Frequency Converter for Lifting is an essential tool for warehousing and distribution centers, enhancing the efficiency and safety of lifting equipment. Its precise control capabilities allow operators to manage forklifts and pallet jacks effectively, ensuring smooth operations during loading and unloading.

Advantages:

Application:

In warehousing and distribution centers, efficient lifting systems are crucial for handling goods and materials. The LP300Q Frequency Converter for Lifting significantly improves the operation of forklifts, pallet jacks, and other lifting equipment by providing precise motor control. This results in enhanced efficiency, safety, and productivity in the warehouse environment.

For instance, during the process of loading and unloading trucks, the LP300Q enables operators to control the speed and precision of lifting equipment effectively. This level of control helps prevent accidents, such as dropping heavy loads or colliding with nearby workers or equipment. Moreover, the LP300Q’s ability to reduce full load current minimizes energy consumption, contributing to lower operational costs.

The LP300Q is also designed with durability in mind, ensuring reliable performance in the demanding conditions of a warehouse. Its compact design allows for easy integration into existing lifting systems, making it a practical choice for facilities looking to upgrade their equipment. In summary, the LP300Q Frequency Converter is vital for improving the efficiency and safety of lifting operations in warehousing and distribution centers.